Allied App protects HVAC Equipment with our SaltShield-386 anti-corrosion coating at our location or on-site:

Extending the operational life of HVAC units

Creating a protective coating formulated with nano-technology penetrating the deepest of crevices

Providing high chemical and UV resistance

Offering the perfect solution for on-site units

Saving customers time with convenient JIT Services

AAC SaltShield-386

Anti-Corrosion Coating

SaltShield-386 is Allied App’s branded name given to the coating formulated by our partner who is a global leader in corrosion control technology and environmentally responsible innovation. Anti-Corrosion Coating development is led by an R&D team whose primary focus is to formulate coatings to meet the needs of the end users’ chemical corrosion challenges. Since 2020, the coating that SaltShield-386 is derived from has been featured in the following Trade publications:

SaltShield-386 is Allied App’s branded name given to the coating formulated by our partner who is a global leader in corrosion control technology and environmentally responsible innovation. Anti-Corrosion Coating development is led by an R&D team whose primary focus is to formulate coatings to meet the needs of the end users’ chemical corrosion challenges. Since 2020, the coating that SaltShield-386 is derived from has been featured in the following Trade publications:

- Materials Performance

- Manufacturing Outlook

- IPCM (International Paint and Coatings Magazine)

- APCJ (Asia Pacific Coatings Journal)

- Gear Technology

- PCE International (The leading Magazine focusing on protective coatings for the marine, offshore structures, and every kind of industrial plant including Paper Mills.)

SaltShield-386 has been selected as the protective coating for the HVAC equipment for one of the nation’s leading Marine Transport Solution Providers. These vessels supply offshore platforms, oil rigs, and Navy ships.

SaltShield-386 has been selected as the protective coating for the HVAC equipment for one of the nation’s leading Marine Transport Solution Providers. These vessels supply offshore platforms, oil rigs, and Navy ships.

We encourage you to contact our sales representatives when you have a unique corrosion issue. Together we can schedule a site visit for a complete evaluation and review of the situation. This detailed information would be shared with our coating manufacturers team of chemists to help determine possible resolutions that maybe available.

HVAC Coating

Our SaltShield-386 coating is perfectly formulated to reach the toughest of crevices in a coil, and tight geometric designed parts such as Micro-Channel.

Allied App Chapin recognizes that Coating Technology is ever changing and improving product performance. Staying with the same product decade after decade is missing out on the expertise of chemist and formulators that tackle corrosion issues in the lab and solve them in the field. We were honored when this leading Corrosion Control Coating manufacturer selected us as their distributor. We were selected for 3 reasons:

- Our marketing team’s knowledge of coatings and expertise in the HVAC industry.

- Our Targeted HVAC Market – they recognized Allied App Chapin as a good partner to expand their coating presence within the HVAC industry.

- Our location – having a physical location in the Carolina’s and the ability to mobilize, combined with an experienced application team made us a logical choice.

Allied App wants our customers to know that the coating being applied to their customers’ products has been formulated with the Best Available Technology. Be assured that as new and better performing coatings become available, they will be introduced to you for evaluation.

One such coating became available in 2020. This new coating has been designed to go over an existing oxidized substrate and has provided a solution for a surface that would have required sandblasting or similar.

Experienced applicators field coat, and meet the challenges that arise to get a quality job completed on time and meet the customers expectations.

Units being prepped for coating.

The team gets a mobile site perfectly level before coating and crane lift.

Units completed and stored at our customer’s warehouse.

Nano VpCI®Technology

WHAT IS IT?

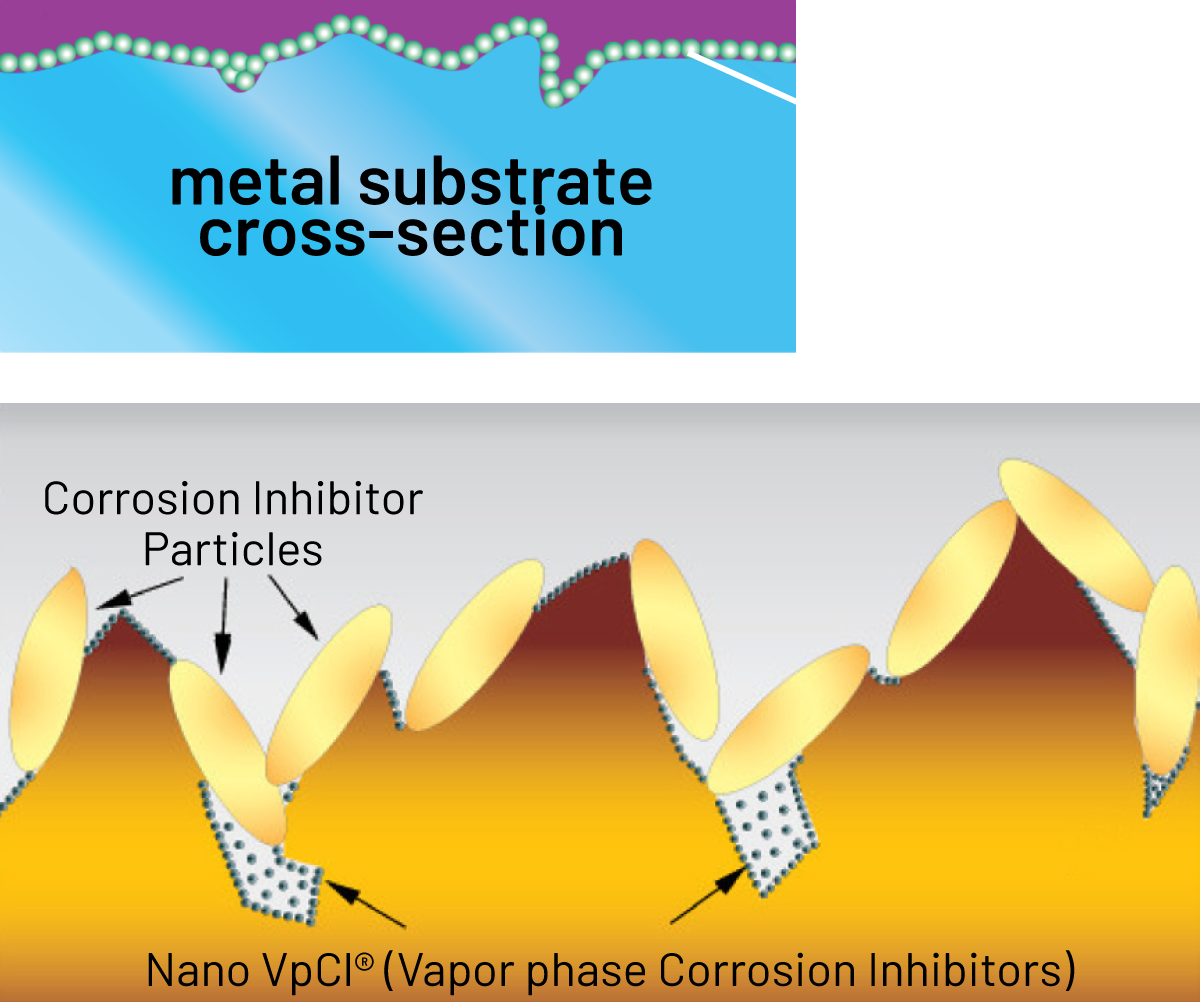

Vapor phase Corrosion Inhibitors (VpCI®) are attracted to the metal surface forming a thin protective barrier against corrosion. In other words, the inhibitors and paint particles within the coating are attracted to the metal through the particle charge.

How does a coating formulated with VpCI® compare to other traditional spray coatings with inhibitors?

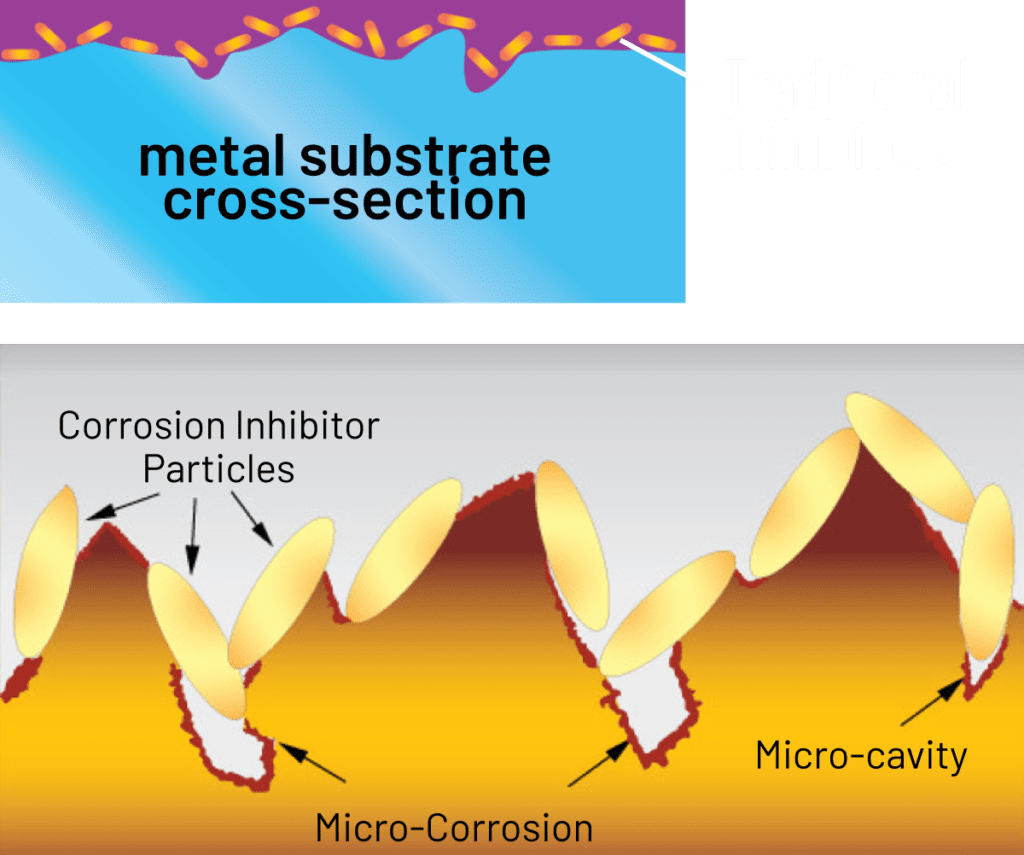

Nano VpCI® technology compares with traditional inhibited coating systems by using smaller particles as well as relying not only on contact inhibition, but also Vapor phase Inhibition. This provides a more complete in-depth coverage and protection of the metal surface (illustration below).

The larger platelets are representative of traditional inhibitors that are unable to fill the micro-crevices, leaving gaps where corrosion could start.

Environmental Advantages of VpCI® Technology over Traditional Inhibited Coatings:

Traditional Inhibitors containing heavy metals (zinc, chromates, aluminum) are becoming increasingly more regulated. The environmental advantage of using an anti-corrosion coating inhibited with Nano VpCI® technology are that they are non-toxic, and do not contain heavy metals.

ArmorShield

ArmorShield is the process of coating the entire unit. This covers the complete exterior and interior, including all components, coils, connections and panels. Fan blades are only coated with approval from the Mechanical Contractor or the end-user. Our interior coating is black, but the exterior coating can be applied in either clear or black.

New equipment that is located in one or more extremely corrosive atmospheres, e.g. on the beach, on a ship, or in a paper mills, a wastewater treatment plant, or an animal processing facility, can become rusting equipment after only a few years in these environments. If the coils are coated, the equipment could be functioning fine but the unit may appear much older than it is and aesthetically adverse.

ArmorShield will protect the entire unit in these environments for many years longer than a unit having only the factory applied coating.

Marketing Team

We at Allied App Chapin are excited to have these two experienced individuals represent the value and services that Allied App brings to the HVAC market here in the Carolina’s and eastern Georgia. We look forward to working with you through in person site visits or ‘Lunch and Learn’ training sessions with your Sales Team, Engineering Team, Architectural Team, and End-Users.

Paul Burns

Paul has spent his career in the Chemical and Coating Industry. Paul has a BS in Business from the University of Louisville. Married to Karen over 30 years, 2 Children, and 2 Grandchildren. Has served as General Manager of a Chemical/Coating distribution and manufacturing facility. His 35-year career has been involved with corrosive chemistries and finding the coating solutions, that are ever developing, to protect the assets of the customer. In the 90’s, Paul was involved with the Coating portion of the company tasked to reformulate anti-corrosion wire coatings that were solvent based – to a water-borne product with no loss in anti-corrosion performance. The success of this coating captured 100% of the international market manufacturing many wire products. Customers not only eliminated the need for solvents, but virtually eliminated their Hazardous waste generation. The last 15 years has been spent in the HVAC Industry, representing coatings that have improved the life of the equipment and coils. Paul’s extensive networking of coating professionals built over the last 3 decades has led to Allied App Chapin landing the distributorship of one of the world leaders in the development of anti-corrosion coatings. Their R&D resources and Technical expertise is now part of the Allied Team.

Jim Auten

Originally from Charlotte, NC moved to Charleston, SC in 2003. Married to Ellen for 30 years and father to awesome twins Clare and Bennett.

Jim attended Erskine College and UNC Charlotte, then started his career in the HVAC industry. Working with one of the top Commercial HVAC manufacturers, Jim focused on National Accounts, Mechanicals, Architects and Engineers. Jim has devoted his efforts within the Carolina’s over the last 25 years. Having spent much of this time within the coastal counties, he has gained a wealth of experience working and consulting with mechanical engineers, OEM field sales representatives and mechanical contractors. His primary focus has been in the commercial industries of Institutional (schools, hospitals etc.), paper mills, wastewater treatment plants, and hospitality. Jim has partnered with Allied App Chapin to represent our corrosion control solutions for HVAC equipment in the Coastal Carolinas & Georgia.